What Has The Greater Impact On Eoq – A Change In S Or A Change In H? Explain.

How often and in what quantity should you club products? This is what we will endeavour to answer in this article with the economic order quantity (EOQ) or Wilson formula.

EOQ formula, step-past-footstep tutorial in Excel:

Economic Order Quantity definition & significant (EOQ)

The Economic Society Quantity (EOQ) is too known as the Wilson formula.

It should be known that Mr. Wilson did not invent the formula. It is rather, Ford Whitman Harris, who developed the mathematical principle. Mr. R. H. Wilson, an industrial consultant specializing in inventory management, then used information technology and practical the formula to optimize inventory.

The EOQ formula aims to find the optimal quantity Q to order for inventory replenishment.

The goal is to find the residue between 2 factors driving the costs: the cost to order and the cost to agree inventory.

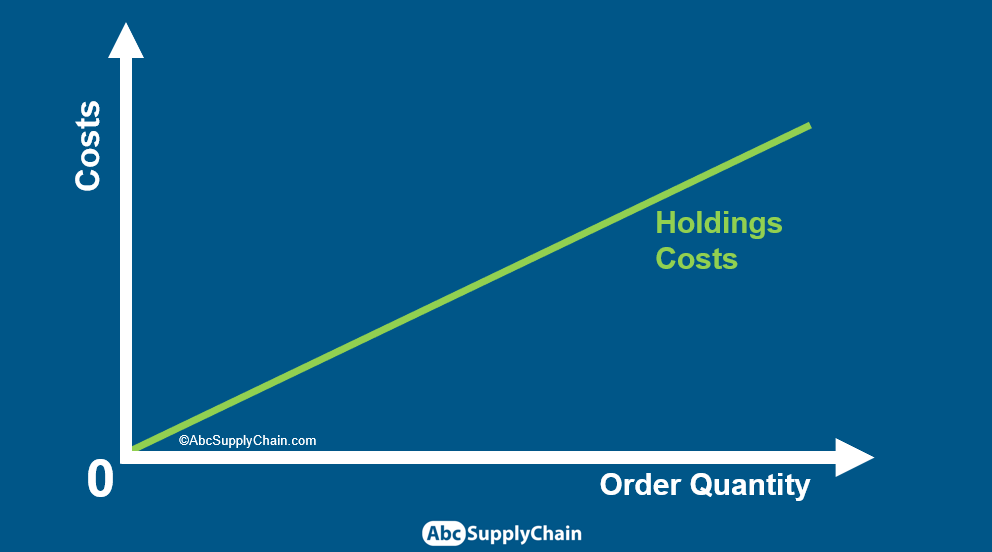

On 1 manus, the more quantities you lot society (Q is big), the more expensive it is. The cost of owning inventory (Holding Costs) will increase proportionally to the quantity, as shown on the graph below:

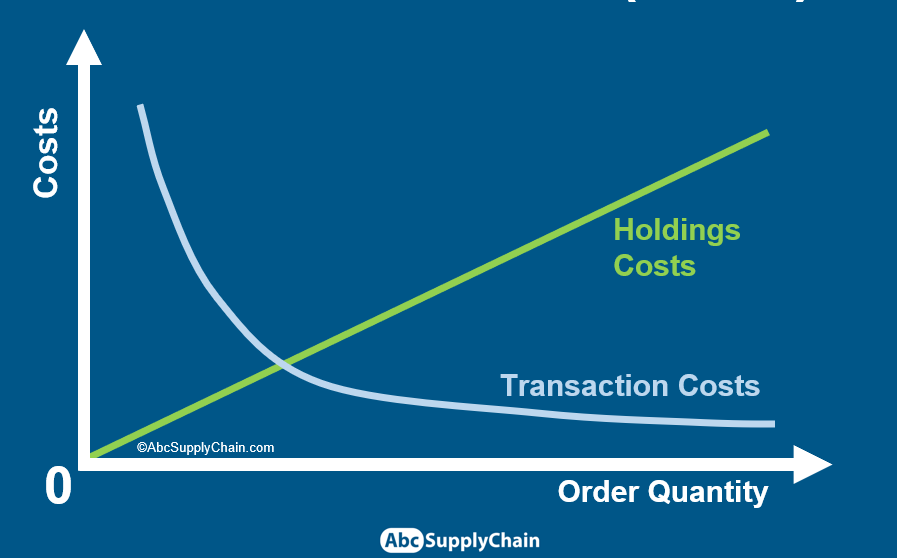

On the other mitt, the more than you lodge at one time (Q is big as well) the less costly information technology is. If you lot sell a thou pieces, it is much more than profitable to society 1000 pieces once, than thousand orders of 1 piece. This ordering price is also known every bit Transaction Price. It is inversely proportional to the quantity ordered:

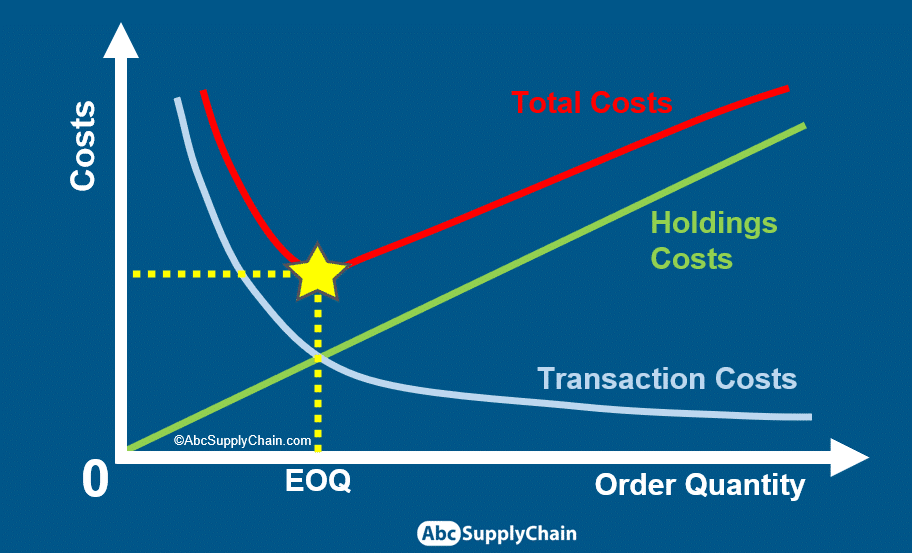

Now allow'south become a look at the Total Costs curve, which is the sum of the Property Costs and Transactions Costs. Nosotros reach the minimum of this curve for a specific Order Quantity, when the Property Costs equal the Transactions Costs. So, by finding the intersection bespeak of the Holding Costs and Transactions Costs curves, we find the less costly quantities to lodge: this is the EOQ.

EOQ Formula

We saw nosotros can solve the EOQ problem graphically. We can also apply directly the mathematical solution.

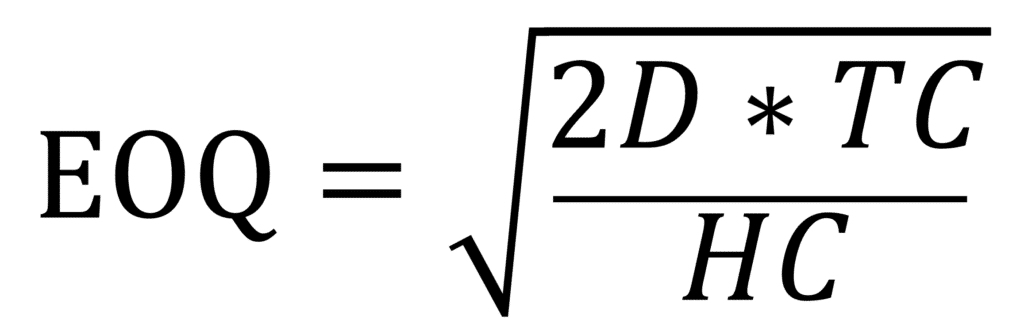

Here is the EOQ formula:

We accept those 3 parameters:

- D = Demand or consumption forecast

- TC = Transaction costs

- HC = Holding costs

EOQ formula: tutorial in Excel

We will now come across examples in Excel. Y'all tin can but download the EOQ Calculator HERE:

Let's take an case with Nike shoes.

Demand

For the Demand, you can take the quantity planned over the desired period (normally 12 months). In this example, we volition take 12,000 thousand pairs of Nike shoes size 43. We assume the demand is abiding over the yr.

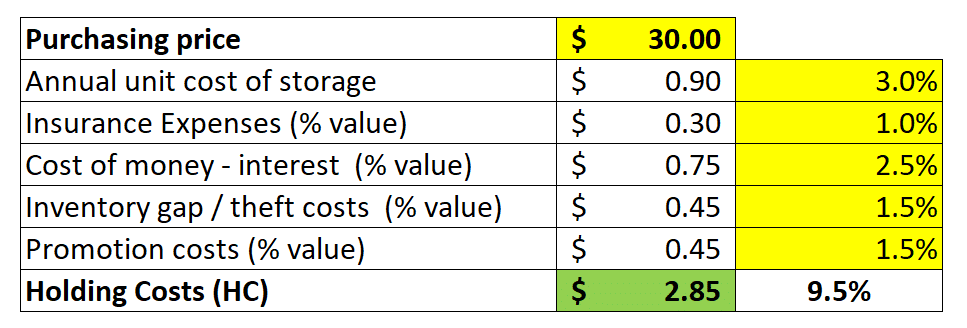

Holding price

The cost of Stock ownership or Holding Stock (HC) is the cost of having a product immobilized in your warehouse, in your store, or in your factory. People frequently tend to underestimate this cost, considering they just consider cash costs and storage costs. However, at that place is much more to take into account:

- Annual unit of measurement cost of storage (in % or in value)

- Insurance costs (a % of the value of your stock)

- Cash costs (credit to finance the stock)

- Theft and inventory gaps

- Promotion costs (promotion volume over the year / total turnover).

In the example above, nosotros use a pct of the Detail Purchase Price. I recommend you to have a chat with your Finance Department to get those values.

The total Holding Costs for our Nike shoes are $two.85, which represents nine.5% of the purchase price.

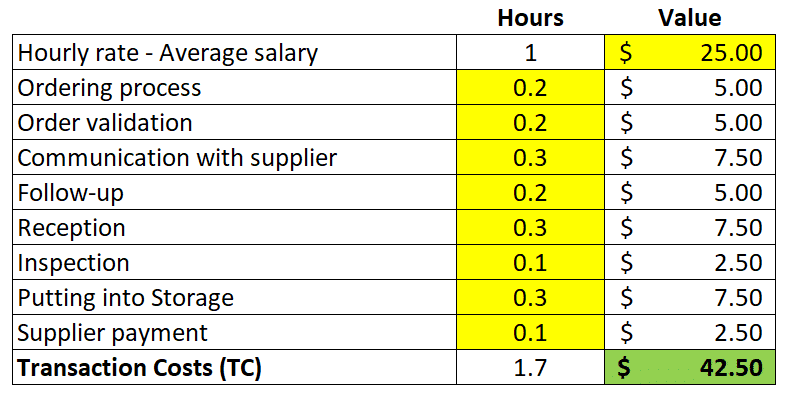

Transaction costs

The cost of placing an order or Transaction Costs (TC) is a picayune more complex considering information technology includes the fixed costs of many processes involved in each order.

In that location are different methods of calculation. You tin starting time take all the departments and people who piece of work on club placement, and divide the full price past the number of orders per year. This method is not optimal: generally, an employee does non work only on orders.

The method I recommend is to try to estimate the number of hours spent on each process. Here are the near common processes listed beneath:

Yous may add or remove processes depending on your specific business organization procedures. You can deduct the cost of each process using an average bacon per 60 minutes.

In this example, nosotros take a total of 1.7 hours to handle i order, which represents $42.5. It is a fixed toll per order.

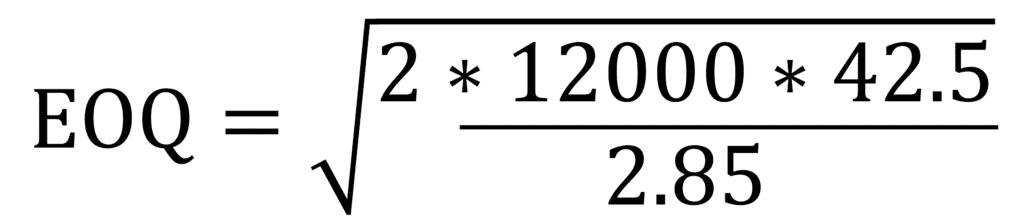

Application of the EOQ Formula

At present, nosotros tin can use the formula:

D = Demand = 12 000

TC = Transaction Costs = $42.5

HC = Holding Costs = $2.85

We go an EOQ of 598 qty. As it is simpler to use round values for order direction, we can round upward the final event:

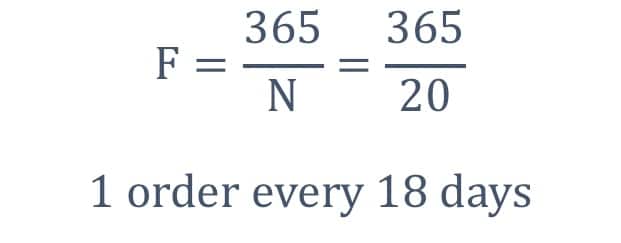

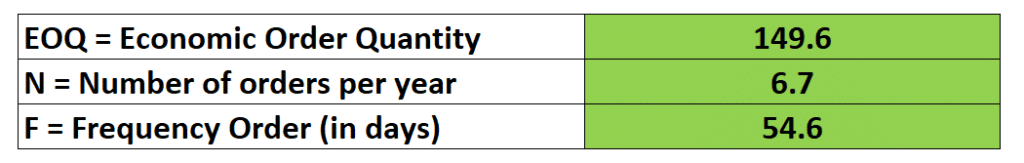

The annual number of orders Due north is given by the almanac demand D divided past the Quantity Q of one order. Thus, for Q = EOQ, nosotros have:

To get the frequency of orders over the yr, we must divide the number of days per year past the number of orders:

Here is a summary diagram of the example:

EOQ Adding: some other instance

We have another pair of shoes, a bit fancier and therefore with lower almanac demand, let's say grand.

The demand is lower, merely the buy price is higher, which leads to a college property cost (HC). The Transaction Costs remain the same.

Because D is lower and HC higher, nosotros end up with a lower Economic Order Quantity: a more than expensive and less demanded product is ordered much less oftentimes.

We order the item every ii months, compared to 18 days in instance 1.

v Limits of the EOQ formula

The EOQ formula has some limits.

The principal problem is that we consider all parameters are constant.

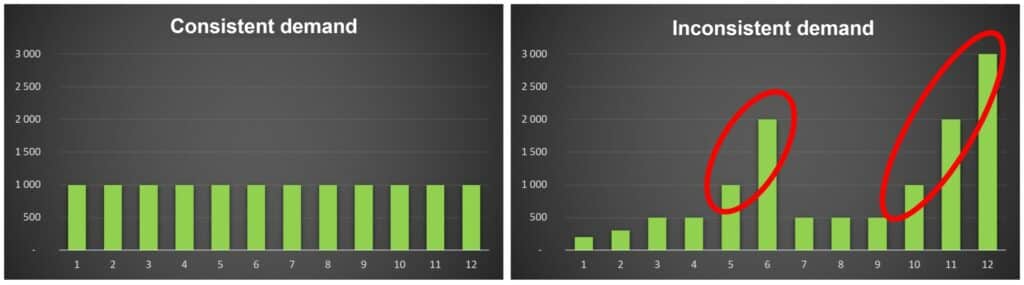

Limit 1: Unstable demand

One of the master assumptions nosotros made is that the demand is constant.

Nonetheless, this is not necessarily the case, and y'all may have an unstable demand with peaks in demand or seasonality.

So, using the previous example, you may non club every xviii days. Otherwise, y'all will be overstocked at a time of depression demand and under-stocked at a time of high demand.

Y'all would need to adjust the frequency of ordering. The fixed EOQ quantity (600 quantities per lodge in the example) remains relevant. In elevation periods, y'all could "grouping orders" and lodge multiples of 600 like 1200, 1800… In low sales periods, you could society less frequently.

Limit 2: The purchase price

Another assumption is the constant buy toll. In full general, suppliers offer discounts depending on the quantities ordered. If so, it is appropriate to tape the purchase prices co-ordinate to different guild levels, as shown in the table below.

Sometimes, the discounts on the purchase price are attractive and make the EOQ analysis much less relevant. In this case, you tin choose to order more quantities per order.

Limit iii: Inconsistent costs

The formula considers that all costs are abiding, including transportation and storage. This is non always the case: for example, you accept stock-still costs in a warehouse (rent, depreciation of machines) simply as well have variable costs like workforce or even electricity.

I suggest you to not seek perfection: focus on what works best. Focus on the costs that take the about impact on your business, and discover an easy way to quantify them (such as a percentage of the purchase price). This volition requite you a good direction.

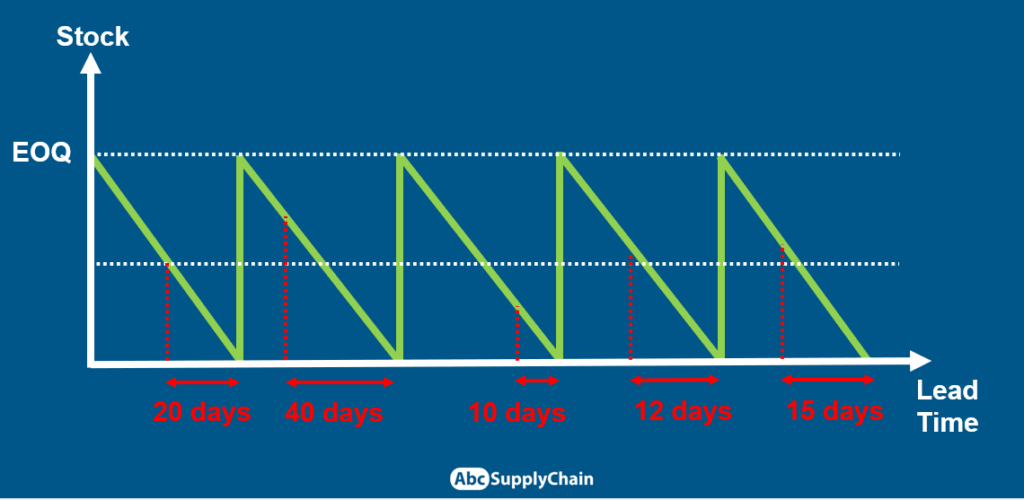

Limit four: Inconsistent or unpredictable lead fourth dimension

The formula considers supply lead fourth dimension as constant. But in reality, lead time may vary over the year, and you take uncertainty near the supply delays.

For case, If you tin can anticipate and see two articulate patterns during the year (big lead time during summertime and shorter ones the residuum of the yr) then you can easily recalculate the EOQ formula. If you lot have high uncertainty on the lead fourth dimension for the whole twelvemonth, then y'all need a deeper analysis.

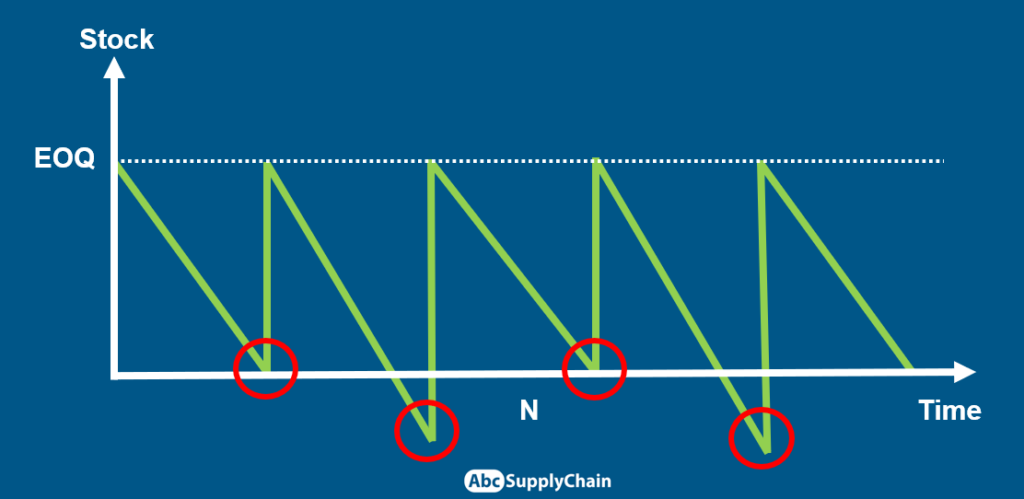

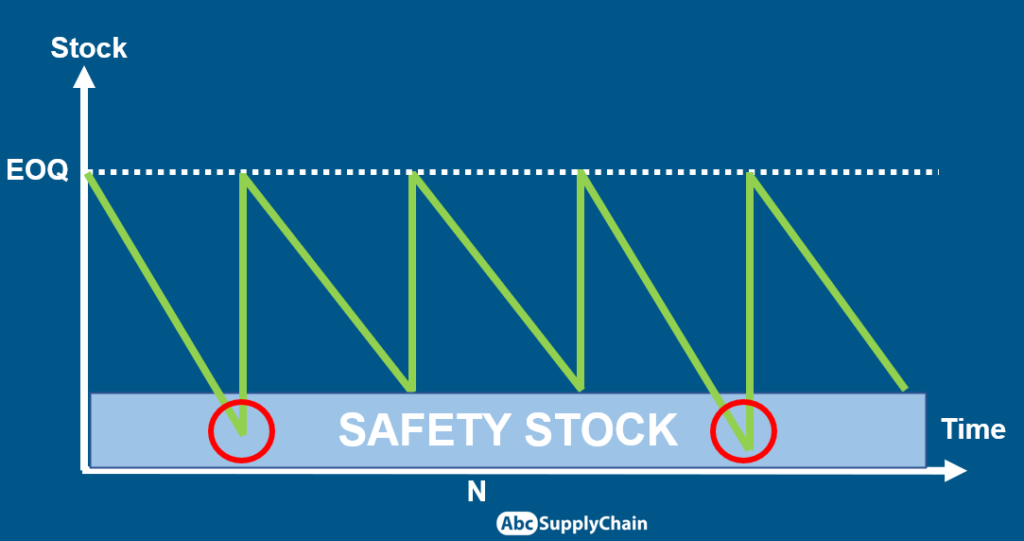

Limit 5: No Safety Stock

Finally, if nosotros assume all parameters are constant and stable, so we do not consider safety stocks. Merely in the reality of the operations, it is impossible to non cover supply and demand risks. Today's markets are more and more volatile and uncertain. Therefore, it is essential to hold safety stocks to face this dubiousness, which tin strongly impact your profits and your client service rate.

Thus, we must combine the EOQ with a safe threshold, every bit shown in the graph below:

To know more nigh Safety Stock calculations, Reorder Signal calculations, and Inventory Direction policies, cheque out my article: Safe Stock Formula & Calculation: 6 best methods.

Conclusion

The Economical Order Quantity is a skillful tool to minimize total costs, as it is the theoretical optimal quantity to order in Inventory Management. We saw how to use the EOQ formula in Excel through various examples, and we deducted the corresponding frequency to order.

The formula itself has limitations. The chief ones are:

- Purchase cost discounts: it can be more bonny in comparison to the EOQ savings. So, the quantities per order tin be bigger than the EOQ.

- Need & Lead time not steady: need to vary the frequency and group orders.

- No Condom Stock: using EOQ doesn't cover any risk

The concluding two problems can be partially solved using a reorder signal policy with safety stocks.

The EOQ formula is an overly simplistic solution to a very broad trouble (every bit with any problem in Supply Chain). Still, it is a practiced starting indicate. Past trying to implement information technology in your inventory management, you will be more aware of your own supply chain challenges.

I have seen then many businesses where order direction was defective the most bones rules or processes. In those cases, implementing simple inventory management principles pace-by-step tin frequently bring bully results.

Take action and don't wait. I like this quote from Jeff Bezos, Amazon'due south CEO:

Most decisions should probably be made somewhere around 70% of the information you wish you had. If you lot wait for 90%, in most cases, you're probably slow.

Jeff Bezos

EOQ: Your Action Plan

- Download the Wilson Formula Excel here, Test it beginning with a few products, the most important for your concern. Then employ it progressively with your entire items' portfolio.

- Summate the EOQ for your business

- Compare the Quantity to order with your electric current settings (important)

- Adjust major deviations

- Review your production batches size / orders / MOQ

To get further, cheque my article: Safety Stock: 6 best formulas to Optimize your inventory

Founder of AbcSupplyChain | Supply Concatenation Expert | 15 years experience in six different countries –> Follow me on LinkedIn

Source: https://abcsupplychain.com/eoq-formula-calculation/

Posted by: schoenbergcontly.blogspot.com

0 Response to "What Has The Greater Impact On Eoq – A Change In S Or A Change In H? Explain."

Post a Comment